1. Introduction

1.1.Definition

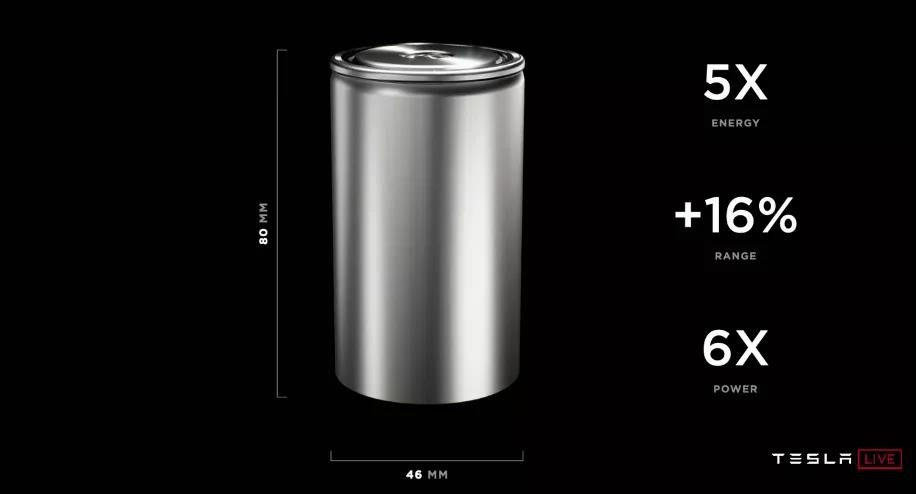

The 4680 battery is Tesla's new generation cylindrical battery with a diameter of 46mm and a height of 80mm.

P1: 4680 battery display diagram

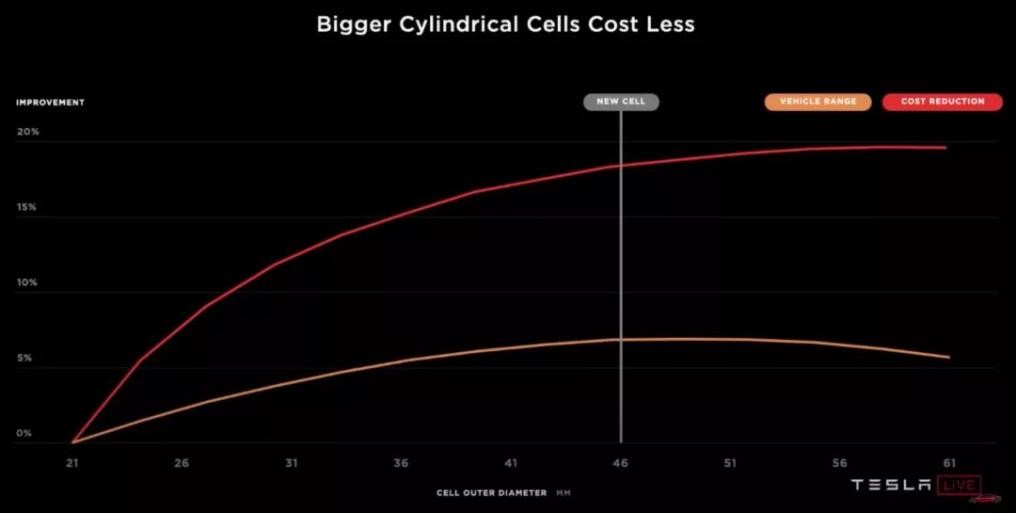

As for the battery, the power density will decrease when the energy density increases. The diameter of 46mm is the optimal choice for the cylindrical battery with both high energy density and high power density.

P2: Changes in size and performance of cylindrical batteries

1.2. Core innovation

Large cell + full pole ear + dry cell technology

1.3. Performance breakthrough

4680 battery greatly improves the battery power (6 times of 2170 battery), reduces the battery cost (14% of 2170 battery), optimize the heat dissipation performance, production efficiency, charging speed, energy density, cycle performance has further room for improvement.

2. Structural change

2.1. Full pole ear

The 4680 battery greatly improves the battery power, optimizes the heat dissipation performance, production efficiency and charging speed by changing the pole lug structure.

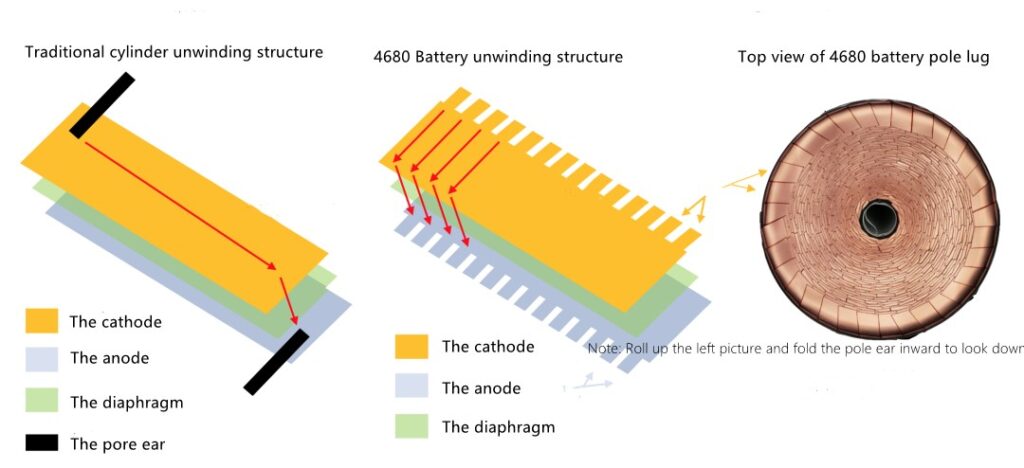

2.1.1. Full pole lug construction

Electrode lug: Metal conductive material that leads the positive and negative electrodes from the cell and is the contact point for charging and discharging of the battery. In the battery work, the electron flows from the positive electrode ear to the negative electrode ear, its flow path is proportional to the battery internal resistance, flow width is inversely proportional to the battery internal resistance, and the battery internal loss power is proportional to the square of the internal resistance, so the larger the contact area of the electrode ear, the shorter the distance between the electrode ear, the higher the battery output power.

Conventional batteries have only two electrodes, one connecting the positive electrode and the negative electrode, but 4680 batteries achieve full electrode ears (directly cut from the positive electrode/negative electrode ear), thus greatly increasing the current path, and shorten the electrode ear spacing, and thus greatly improving the battery power.

P3

2.1.2.Advantages of full pore ear

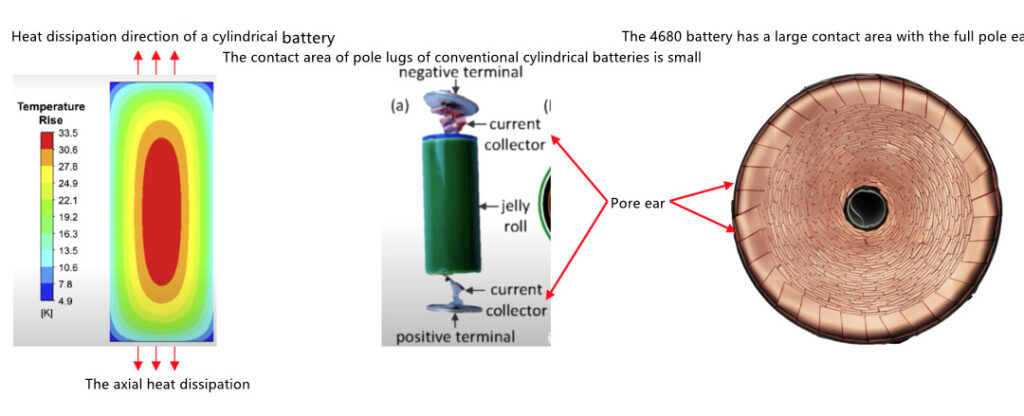

1. Improved output power: the battery current path becomes wider, and the internal resistance is greatly reduced, so the internal loss is reduced, and the battery power is greatly increased (6 times that of the 2170 battery).

2. Improve safety: cylindrical battery is different from sheet battery. Its heat dissipation is mainly axial, and the heat is scattered from the pole ear. Conventional cylindrical batteries such as 2170 have only two lugs and narrow heat transfer channels, so the heat dissipation effect is not good. The 4680 battery has a large increase in pole ear area and a wide heat transfer channel, which greatly improves the heat dissipation effect (only 20% of the traditional cylindrical battery) and enhances the thermal stability of the battery.

3, fast charging performance is greatly improved: due to the full pole ear structure, electrons are easier to move in the battery, the current ratio is improved, so the charging and discharging speed is faster.

- Improve production efficiency: eliminate the process and time of adding pole ears on production line, save equipment space and reduce the possibility of manufacturing defects.

P5

3.Dry cell technology

Dry electrode technology can be used for both positive and negative electrodes.

3.1. Traditional wet process

The material needs to be placed in solution, then dried and pressed into film: Using solvent adhesive materials, including NMP (N-methylpyrrolidone) is one of the common solvents, and will be of adhesive solvent mixes with negative or positive electrode powder, the slurry coating on the electrode set electricity body and dry, the solvent toxic, to be recovered for purification and recycle, the intermediate need large, expensive and complex electrode coating machine.

3.2. Dry cell process

Dry electrode process completely skips the step of adding solution, can omit the complicated coating, drying and other processes, greatly simplifies the production process: the active positive and negative particles and polytetrafluoron (PTFE) mixed, make its fibrosis, directly with powder rolling into a film pressed to aluminum foil or copper foil, the preparation of positive and negative pieces.

3.3. Advantages of dry batteries

1, the process is simple, cost saving: no solvent, eliminating the expensive coating machine.

2, improve production efficiency: dry electrode technology to increase the production speed to seven times before.

3, increase the battery energy density: in the case of solvent, lithium and carbon mixed with lithium metal can not be well integrated with each other, there is a first cycle capacity loss problem, dry battery technology will greatly improve this problem, so as to improve the battery energy density. At the same time, the thickness of positive electrode material was increased from 55μm to 60μm to improve the ratio of active electrode material, and the energy density was increased by 5% while ensuring the power density.

3.4. Dry battery process difficulties

The current process is not mature, the battery should be thick, the cylinder should be rolled up, easy to crack.

4. The silicon anode

4.1.Advantages

1.Higher theoretical energy density: graphite anode theory maximum battery capacity 372Wh/kg, silicon anode theory maximum battery capacity up to 4200Wh/kg.

2.Better safety: silicon voltage platform is higher than graphite, now anode graphite will produce lithium dendrite, because their voltage platform is close to the precipitation potential of lithium, branch crystal pierced diaphragm, positive and negative poles will short-circuit, serious threat to battery safety.

3.Lower cost: silicon material is widely sourced, abundant in reserves, low production cost and environmentally friendly. Lithium-ion batteries using silicon anode materials can increase their mass energy density by more than 8 percent and volume energy density by more than 10 percent, while reducing their cost per kilowatt-hour by at least 3 percent.

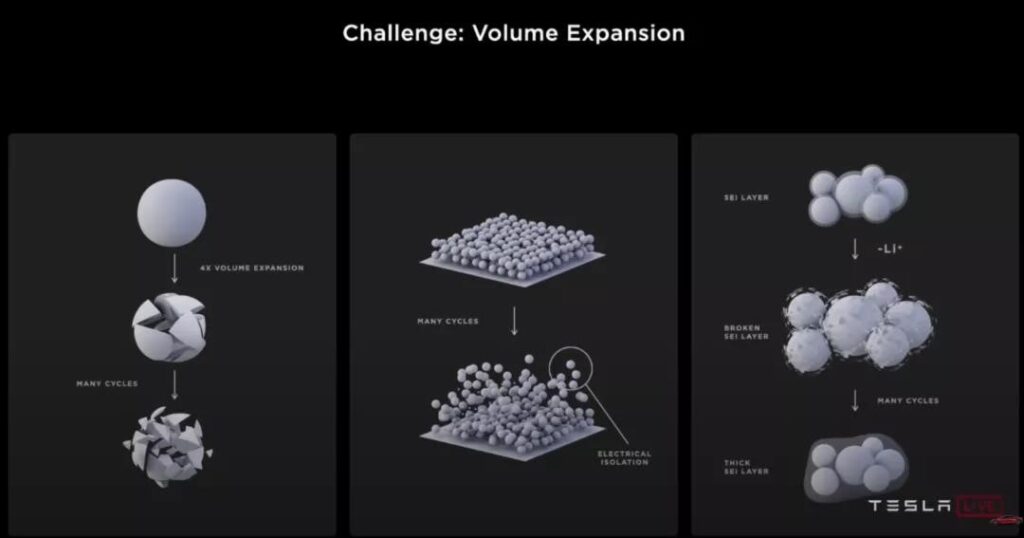

4.2. Disadvantages

1. Poor cycling performance: after embedding lithium, the volume of graphite does not expand significantly after embedding lithium ions, but the volume of silicon expands more than four times after embedding lithium ions, and the battery is scrapped after several times of expansion and contraction.

2.Poor conductivity: the low conductivity of silicon limits the full use of its capacity and the rate performance of silicon electrode materials; The change of volume makes the contact between active substance and conductive binder poor, and the conductivity decreases. SEI film on silicon surface is thick and uneven, which affects the conductivity and the overall specific energy of the battery.

4.3. 4680 Battery Innovative design

Tesla's redesign of the raw material to use a highly elastic material and an ionic polymer coating that increases elasticity can stabilize the silicon surface structure and reduce costs by 5%.

P6:Tesla silicon anode process principle

5. Conclusion

4680 battery core innovation process: large cell + full pole lug + dry cell technology, enhance battery power and safety, improve production efficiency, fast charging performance, reduce battery cost, energy density, cycle performance has further improved space. At present, the difficulty lies in the fabrication, welding and dry electrode process of the whole electrode lug. 4680 battery was first applied in high nickel system. It is expected that Tesla and Panasonic will start mass production in the first half of 22, which will drive the demand of high nickel positive electrode + silicon carbon negative electrode + carbon nanotube conductive medium + large cylindrical structure parts + new lithium salt, and the corresponding tap will benefit. Yiwei is leading the layout of large cylindrical batteries in China, and plans to invest 20GWh capacity, which is expected to be increased in 23 years.

- 3C batteries (1)

- 48C Advanced Energy Project Credits (1)

- ActiveBalancing (1)

- Advanced Storage Solutions (1)

- advanced technologies (1)

- African market (1)

- AI Algorithms (1)

- AI in Energy Storage (1)

- air conditioning (1)

- All-in-One Energy Storage (1)

- American electricity market (1)

- ancillary services market (1)

- application scenarios (2)

- Arnstadt (1)

- automotive industry (1)

- backup generators (1)

- Backup power (1)

- batteries (2)

- Battery Discharge (1)

- Battery Energy Storage (1)

- Battery Energy Storage Systems (1)

- Battery Energy Storage Systems (BESS) (1)

- battery factory (1)

- battery industry event (1)

- battery management system (3)

- battery management systems (1)

- battery market (1)

- battery materials (1)

- battery pack (1)

- Battery Storage Safety (1)

- Battery technologies (1)

- battery technology advancements (1)

- battery type (1)

- BatteryLongevity (1)

- BatteryManagementSystem (1)

- BatterySafety (1)

- BatteryTechnology (1)

- BESS (1)

- Birmingham Exhibition (1)

- BMSArchitecture (1)

- Brazil energy storage (1)

- Burkina Faso (1)

- Capacity (1)

- capacity rule (1)

- carbon management (1)

- carbon neutrality goals (1)

- CATL (1)

- CE marking (1)

- certification (1)

- certifications (1)

- Charge Current (1)

- Charge/Discharge Rate (1)

- Chemical Storage (1)

- China electricity market (1)

- China International Battery Fair (1)

- CIBF 2023 (1)

- Clean energy (6)

- clean energy incentives (1)

- Clean Energy Revolution (1)

- clean energy solutions (1)

- Climate Goals (1)

- Climate Legislation (1)

- Commercial (1)

- Commercial Energy Storage (2)

- CompleteCurrentControl (1)

- Compressed Air Energy Storage (CAES) (1)

- consumer batteries (1)

- Containerized Energy Storage (1)

- Continuous Discharge Duration (1)

- conversion efficiency (1)

- Cooperation (1)

- cost composition (1)

- cost parity (1)

- cost reduction (1)

- Cost-effective storage (1)

- critical power (2)

- CSA certification (1)

- Customized Energy Storage (1)

- DC bus voltage (1)

- Decarbonization (1)

- Decarbonized future (1)

- Demand Forecasting (1)

- Department of Energy (1)

- DesignConsiderations (1)

- development strategies (1)

- Direct Pay (1)

- Discharge Current (1)

- discharge curve (1)

- Distributed Energy (1)

- Dongguan Lithium Valley (2)

- dual carbon goal (1)

- Dubai World Trade Center (1)

- efficient energy storage (1)

- Electric Vehicle Charging (1)

- Electric Vehicles (2)

- Electricity Costs (1)

- Electricity Infrastructure Operations Center (1)

- electricity market (1)

- electricity price mechanism (1)

- electricity prices (1)

- electricity supply (1)

- electrochemical energy storage (1)

- Electrochemical Storage (1)

- Energy Certification (1)

- Energy Community Adder (2)

- energy companies (1)

- energy consumption (1)

- energy consumption management (1)

- energy crisis (1)

- Energy Demand (1)

- Energy Demands (1)

- energy density (2)

- energy distribution (1)

- Energy Efficiency (1)

- energy industry (1)

- Energy Industry Solutions (1)

- energy investment (1)

- Energy Landscape (1)

- Energy Management System (3)

- energy management systems (1)

- energy professionals (1)

- energy sector (1)

- energy solutions (2)

- Energy storage (16)

- Energy Storage Batteries (3)

- Energy storage battery business (1)

- Energy Storage Battery Industry (1)

- Energy Storage Battery Technology (1)

- energy storage business model (1)

- Energy Storage Cabinets (1)

- energy storage capacity (1)

- Energy Storage Certification (1)

- Energy Storage Challenges (1)

- energy storage components (1)

- energy storage converters (1)

- energy storage equipment (1)

- Energy Storage Incident (1)

- energy storage industry (4)

- energy storage market (1)

- Energy Storage Products (1)

- energy storage profitability (1)

- energy storage projects (1)

- Energy storage research (1)

- Energy Storage Solution (2)

- Energy Storage Solutions (4)

- Energy Storage System (3)

- energy storage system solutions (1)

- Energy Storage Systems (5)

- Energy Storage Technologies (2)

- Energy Supplies (1)

- Energy Supply Challenges (1)

- Energy Transition (1)

- energy trends (1)

- EnergyEfficiency (1)

- EnergyStorage (1)

- Environmental Innovation (1)

- environmental sustainability (1)

- ESS chain (1)

- EU countries (1)

- European battery factory (1)

- European electricity market (1)

- European Market (1)

- European Solar Market (1)

- Exhibitors (1)

- Extended Tax Credits (1)

- field study (1)

- financing options (1)

- fire protection systems (1)

- Flexibility (2)

- Flow batteries (2)

- Flywheel Energy Storage (1)

- Fossil Fuel Emissions (1)

- fossil fuels (1)

- generation side (1)

- Germany (2)

- Gigawatts (1)

- Global Carbon Emissions (1)

- global energy storage (1)

- global market share (1)

- global power batteries (1)

- government officials (1)

- Government Support (1)

- granular silicon (1)

- Green Energy Initiatives (1)

- Green Living (1)

- Green Technology (2)

- Greenhouse Gas Emission Verification (1)

- grid (1)

- Grid reliability (2)

- grid resilience (1)

- grid side (1)

- Grid Stability (3)

- Grid Storage Launchpad (1)

- grid voltage (1)

- grid-connected (1)

- Guide (1)

- high-voltage battery (1)

- higher discharge rate (1)

- Home Energy Storage (3)

- Home Energy Storage Benefits (1)

- household energy storage (2)

- hydropower (1)

- I&C energy storage (1)

- IEC 62619 (2)

- IEEE 1547 (1)

- inductive loads (1)

- Industrial (1)

- industrial and commercial energy storage (1)

- industrial and commercial track (1)

- Industrial Energy Storage (6)

- Industry Trends (1)

- IndustryStandards (1)

- Inflation Reduction Act (1)

- Inflation Reduction Act (IRA) (1)

- installed energy storage (1)

- integrated energy storage cabinet (1)

- integration (1)

- intelligent solutions (1)

- Intermittency (1)

- International Energy Agency (1)

- International Energy Agency (IEA) (1)

- International Energy Storage Exhibition (1)

- Intersolar (1)

- Intersolar Europe 2023 (1)

- Intersolar Middle East (1)

- Intertek (1)

- inverter (2)

- inverter power (1)

- Investment (1)

- Investment Tax Credits (1)

- ISO 14001 (1)

- ISO 9001 (1)

- ITC (1)

- Johannesburg (1)

- large size silicon (1)

- large-scale energy storage (1)

- Leveraging Solar Power (1)

- life cycles (1)

- LiFePO4 batteries (1)

- lithium batteries (1)

- lithium iron phosphate batteries (2)

- Lithium Prices (1)

- Lithium Valley (14)

- Lithium Valley Products (1)

- Lithium Valley Technology (1)

- Lithium-ion alternatives (1)

- Lithium-Ion Batteries (3)

- lithium-ion battery cells (1)

- lithium-ion voltage (1)

- load capacity (1)

- Long Beach California (1)

- Long Duration Energy Storage (1)

- Long-duration storage (2)

- Low-carbon Future (1)

- low-voltage battery (1)

- LS Energy Solutions (1)

- M&A project (1)

- manufacturing equipment (1)

- Market Opportunities (1)

- market-oriented (1)

- Mechanical Storage (1)

- MEE (1)

- merger agreement (1)

- Microgrids and Distributed Energy (1)

- Middle East Energy Summit (1)

- Mobile Energy Storage (1)

- Multiple-MPPT (1)

- Na+ battery (1)

- Net Zero Emissions (2)

- Netherlands (1)

- new energy battery technology (1)

- Next-generation batteries (1)

- North America (1)

- NREL (1)

- off-grid (1)

- oil and gas (1)

- operating efficiency (1)

- optical storage (1)

- Pacific Northwest National Laboratory (1)

- PassiveBalancing (1)

- Peak Times (1)

- peak-valley price difference (1)

- Photovoltaic (PV) Solar Power (1)

- photovoltaic components (1)

- photovoltaic installations (1)

- plug-and-play (1)

- policy certainty (1)

- polysilicon (1)

- power batteries (1)

- power battery company (1)

- power battery developments (1)

- power conversion system (1)

- power density (1)

- Power Generation (2)

- power match (1)

- power supply (1)

- power system (1)

- power systems (1)

- power transmission (1)

- Power/Energy (1)

- Predictive Analytics (1)

- Product Carbon Footprint Certificate (1)

- product line (1)

- product upgrades (1)

- production capacity (2)

- production process (1)

- profit model (1)

- Pumped Hydro Storage (1)

- quality management system (1)

- R&D team (1)

- raw materials (1)

- regional energy transformation (1)

- Reliability testing (1)

- Reliable Power Supply (1)

- renewable energy (18)

- renewable energy capacity (1)

- Renewable Energy Industry (1)

- Renewable energy integration (2)

- renewable energy investment (1)

- renewable energy policies (1)

- renewable energy production (1)

- Renewable Energy Revolution (1)

- Renewable Energy Solutions (1)

- renewable energy sources (1)

- Renewable Energy Storage (1)

- RenewableEnergy (1)

- renewables sector (1)

- Residential & Commercial Energy Storage (1)

- residential energy storage (2)

- rural energy storage (1)

- safer energy storage (1)

- Sandton Convention Centre (1)

- Scalability (1)

- service life (1)

- shadow scan function (1)

- signing ceremony (1)

- silicon materials (1)

- silicon wafers (1)

- single-cluster battery management (1)

- Single-MPPT (1)

- smarter energy storage (1)

- SNEC Exhibition (1)

- Sodium-ion batteries (1)

- Sodium-ion Battery (1)

- Solar & Storage Live 2023 (1)

- Solar Capacity (1)

- solar cells (1)

- Solar Energy (2)

- Solar Energy Industry (2)

- solar energy products (1)

- solar energy storage (1)

- Solar Energy Technologies (1)

- Solar Generation (1)

- Solar Installations (1)

- solar integration (1)

- solar modules (1)

- solar panel energy storage (1)

- solar power (2)

- Solar PV (1)

- Solar Show Africa 2023 (1)

- Solar Sustainability (1)

- solar trends (1)

- Solar-Plus-Storage Integration (1)

- Solid-State Batteries (1)

- South African Minister of Energy (1)

- Stacked High-Voltage Battery (1)

- standardization (1)

- StateEstimation (1)

- Storage Installations (1)

- Storage Ratio (1)

- Storage Systems (1)

- Strategy Director (1)

- SUMEC (1)

- Supplier Conference (1)

- supply chain cost (1)

- Supply Chain Traceability (1)

- surge power (1)

- Surplus Energy (1)

- Sustainability (1)

- Sustainable Development (1)

- Sustainable Energy (2)

- Sustainable Future (1)

- Sustainable Power Grid (1)

- sustainable power solutions (1)

- Sustainable Practices (1)

- Sustainable Technology (1)

- SustainableEnergy (1)

- system structure (1)

- TD (1)

- technical components (1)

- Technological Innovation (2)

- technology exchange (1)

- Temporary Power Solutions (1)

- ternary lithium batteries (1)

- Thermal Storage (1)

- Thuringia (1)

- Transferability (1)

- transparent reporting (1)

- TUV certification (1)

- Types of Energy Storage Systems (1)

- UK (1)

- UK Legislation (1)

- UL 1973 (2)

- UL 9540A (1)

- US Federal Government (1)

- US manufacturers (1)

- US public investments (1)

- user side (1)

- Utilities (1)

- voltage match (1)

- wholesale market (1)

- Wind Capacity (1)

- Wind Energy (1)

- Wind Generation (1)

- Wind Installations (1)

- wind power (1)

- winter energy demand (1)

- Zero Emissions (1)

- Zonsen Power (1)

- ZZonsen Power (1)